Design & Applications

The inlays are ready for converting into various types of smart labels / tickets / tags as typically used for RFID applications in:

- Logistics

- Asset management

- Supply chain management

- Transportation

- Identification and authentication

- NFC

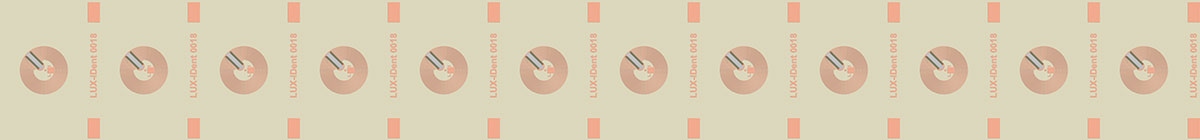

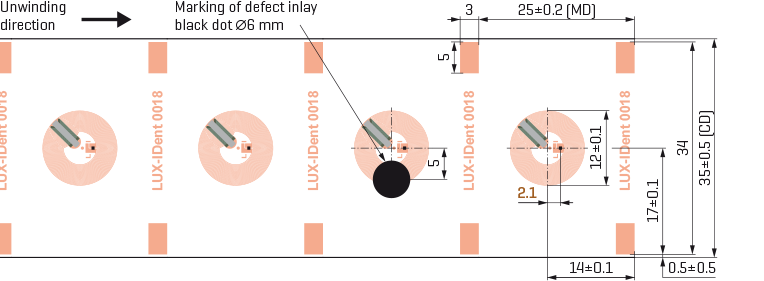

Inlay overview with dimensions – in reel format (mm)

The chip position in MD direction can vary depending on the inlay tuning frequency and chip size (type).

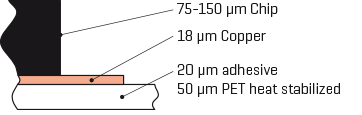

Cross section

RFID chip types

| Manufacturer Standard |

Chip type |

| NXP | |

|---|---|

| ISO 15693 ISO 18000 3M3 |

ICODE® family |

| ISO 14443A | MIFARE Ultralight®, MIFARE Plus®, MIFARE® DESFire®, NTAG™ family |

| NFC | MIFARE Classic® EV1, MIFARE Ultralight®, MIFARE Plus®, MIFARE® DESFire®, NTAG™ family |

| Infineon | |

| ISO 15693 | my-d™ vicinity |

| ISO 14443A | my-d™ proximity, my-d™ move, SLE77xxx (A/B), CIPURSE™ move |

| NFC | my-d™ NFC, my-d™ move NFC, CIPURSE™ move |

| STMicroelectronics | |

| ISO 15693 | ST25TVxxx family |

| ISO 14443A | ST25TAxxx family |

| NFC | ST25TAxxx family |

| EM Microelectronic | |

| ISO 15693 | EM4237 SLIC/SLIX |

| NFC | EM4423(HF) |

| Fujitsu | |

| ISO 15693 | MB89R‑family |

Other ICs are available upon request.

Reliability

| Operation temperature | −25°C to 70°C/85°C, depending on chip specification |

|---|---|

| Storage conditions | 1 year at 10°C to 25°C, maximum 60% relative humidity |

| Thermal humidity test | 168h at 85°C / 85% humidity |

| Temperature cycle resistance | 250 cycles at −40°C to 85°C |

| Bending |

Chip upside: ∅ 30mm

Chip downside: ∅ 40mm

|

| Shear force onto chip | 10N / mm² chip area |

| ESD voltage immunity | ±2kV max. peak – human body model (HBM) accord. to chip specification |

Inlay delivery details

| Quantity on reel | 5,000 / 10,000 |

|---|---|

| Reel dimension | ∅ Reel: 265 mm / 365 mm ∅ Core: 76.2 mm (3”) |

| QC inspection inline | 100% electrical UID test with bad marking of rejected inlays |

Product codes

L15-D012A11-xxx (17pF)

L15-D012B11-xxx (23.5pF)

L15-D012C11-xxx (50pF)

L15-D012D11-xxx (70pF)

HF & NFC Inlay

HF & NFC Inlay